GENKX stands as a national high - tech enterprise, seamlessly integrating R&D, production, sales, and service of new energy battery pack products, including lithium batteries, energy storage systems, and power systems.

Our core team brings over 20 years of invaluable experience in the energy storage industry. Driven by the business philosophy of “Unmatched Quality, Revolutionary Progress, Iterative Refinement, Exceptional Service”, we are committed to evolving into a globally excellent new energy battery storage system solutions provider.

Our vision is to be the world's outstanding smart energy storage system solution provider, and our mission centers on making green energy storage safer, more reliable, and more economical, while upholding values of innovation, excellence, customer success, and employee well - being.

The core team of GENKX New Energy has over 10 years of experience in the lithium industry, and will strive to build advanced technological capabilities, systematic automated production processes, and a comprehensive quality management system.

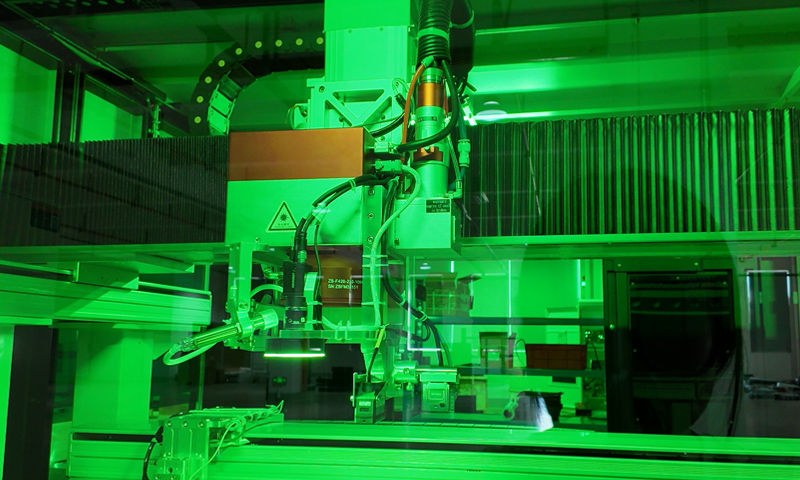

Genkx Engineering is equipped with high - quality production equipment for energy storage product assembly, including fiber laser pipe cutting machines, fiber laser cutting machines, CNC bending machines, nitrogen generators for laser cutting, hook - type shot blasting machines, crawler - type shot blasting machines, vertical forward - reverse powder spraying reciprocating machines, Canop industrial robot control cabinets, continuous fiber laser welding machines, hand - held laser welding machines, inverter - type gas - shielded welders, and battery pack lines.

The fiber laser pipe cutting and cutting machines enable high - precision cutting of various components for energy storage products, ensuring accurate dimensions and smooth cuts, which is crucial for the proper assembly and performance of energy storage systems. The CNC bending machines allow for precise bending of metal parts, contributing to the structural integrity of energy storage enclosures and frames.

Nitrogen generators for laser cutting provide a stable nitrogen environment during the cutting process, preventing oxidation and ensuring the quality of cut surfaces, which is beneficial for the long - term reliability of energy storage products. Hook - type and crawler - type shot blasting machines effectively clean the surfaces of parts, enhancing the adhesion of subsequent coatings and improving the corrosion resistance of energy storage equipment.

Vertical forward - reverse powder spraying reciprocating machines ensure uniform and thorough powder coating, providing a durable and protective finish for energy storage products, especially important for those used in various environmental conditions. Canop industrial robot control cabinets enable automated operations in the assembly process, improving production efficiency and consistency.

Continuous fiber laser welding machines and hand - held laser welding machines offer versatile and high - quality welding solutions for different components of energy storage products, ensuring strong and reliable joints. Inverter - type gas - shielded welders are used for specific welding tasks, guaranteeing the quality of welds in the assembly.

The pack lines integrate the assembly process, streamlining the production of energy storage packs, from component assembly to final testing, ensuring efficient and standardized production.

Every staff member in the workshop of Genkx Engineering is proficient in energy storage product assembly and mechanical specialties, complementing the advanced equipment to ensure the high quality and reliability of energy storage products.

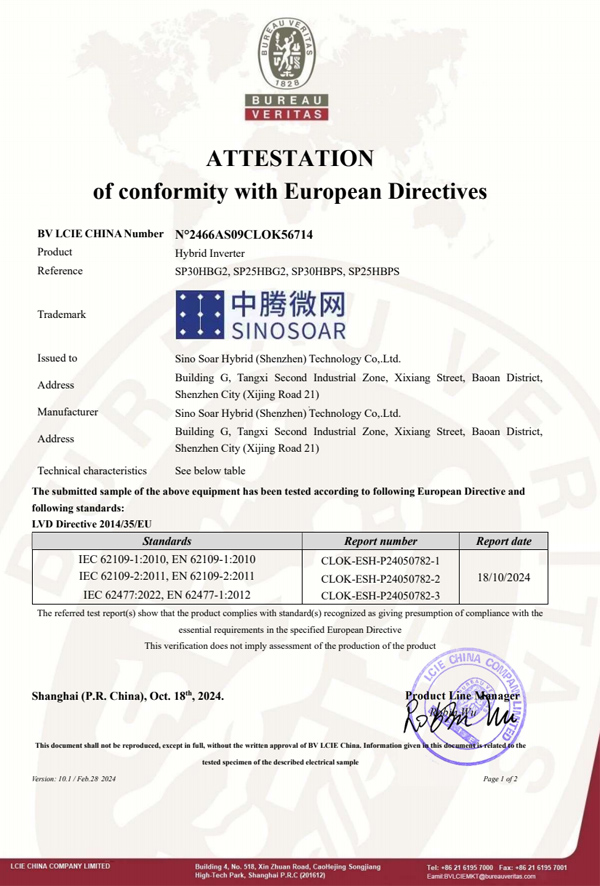

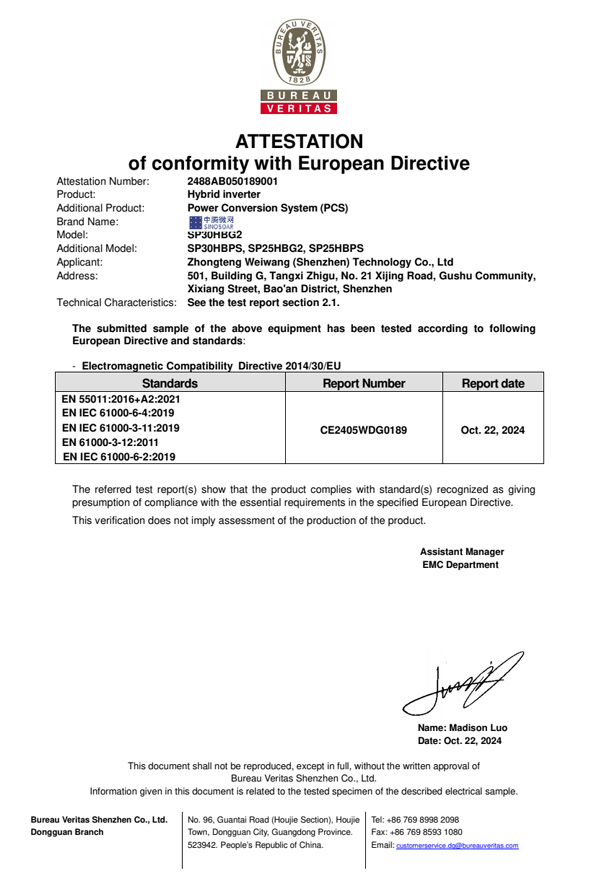

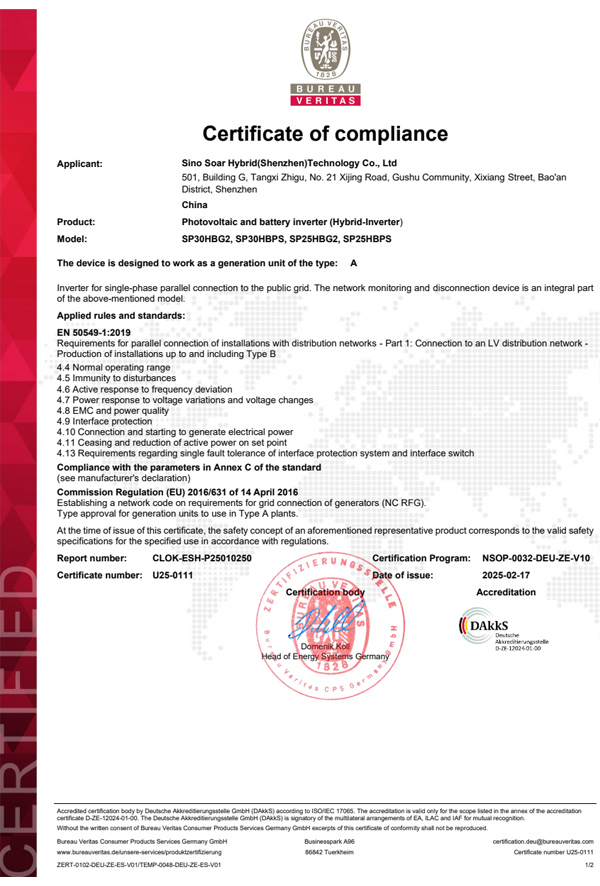

We've observed that customers place stronger trust in our capabilities, thanks to our collaboration with inverter suppliers boasting a robust certification portfolio. These partners hold certifications tailored to diverse global markets, ensuring compliance across regions.

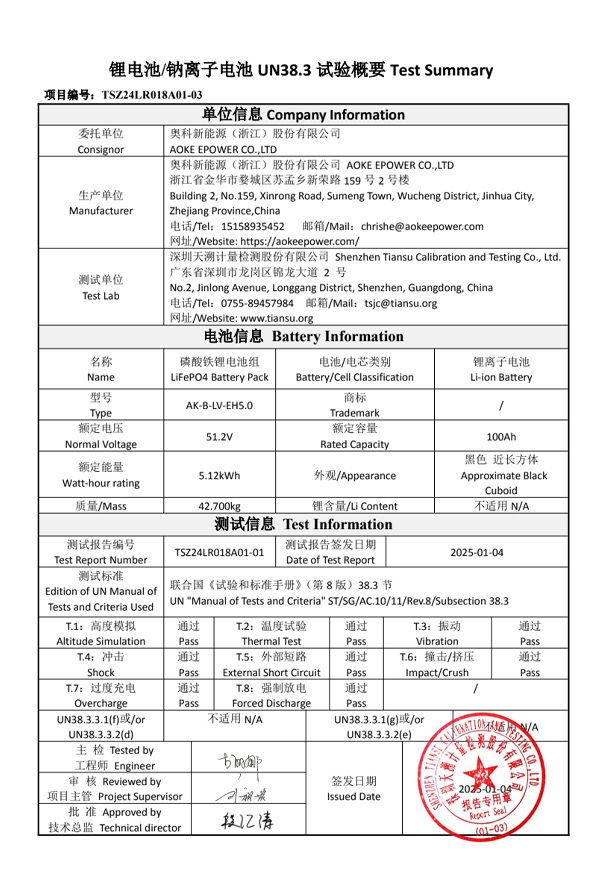

For batteries, we provide products equipped with essential safety and transportation credentials: all come with MSDS (Material Safety Data Sheet), UN38.3 (UN Test and Certification of Lithium - ion Batteries) for lithium - based units, and Marine Transport Appraisal Reports to guarantee smooth logistics.

Beyond standard certifications, we offer full flexibility—if customers require specific market - oriented or project - unique certificates, our suppliers will tailor them to meet precise demands.

This commitment to certification not only reflects our adherence to international quality and safety norms but also serves as a testament to our ability to deliver compliant, reliable energy storage solutions worldwide.

UN38.3 Test Report

Quality Management system certificate

Material Safety Data Sheet

Lithium Battery/Sodium-ion Battery UN38.3 Test Summary

ATTESTATION of conformity with European Directives

ATTESTATION of conformity with European Directives2

Certificate of compliance

Qualification information of GENKX generator suppliers

Chris@genkx.com

Chris@genkx.com +86-17757961911

+86-17757961911 No.159 Xinrong Rd,the New Energy town, Jinhua321000

No.159 Xinrong Rd,the New Energy town, Jinhua321000Copyright © 2025 GENKX All Right Reserved. Designed & SEO by followala.cn Sitemap | XML